Appendix G.10

G.10 Import of MOE Water Well Database

- Tables (OAK_20160831_MASTER compatible)

- D_BOREHOLE

- D_BOREHOLE_CONSTRUCTION

- D_DATA_SOURCE

- D_GEOLOGY_FEATURE

- D_GEOLOGY_LAYER

- D_INTERVAL

- D_INTERVAL_MONITOR

- D_INTERVAL_REF_ELEV

- D_INTERVAL_TEMPORAL_2

- D_LOCATION

- D_LOCATION_ALIAS

- D_LOCATION_GEOM

- D_LOCATION_PURPOSE

- D_LOCATION_QA

- D_LOCATION_SPATIAL

- D_LOCATION_SPATIAL_HIST

- D_PUMPTEST

- D_PUMPTEST_STEP

- Tables (MOE Water Well Database, MOE_20170905)

- TblBore_Hole

- TblCasing

- TblFormation

- TblHole

- TblMethod_Construction

- TblPipe

- TblPlug

- TblPump_Test

- TblPump_Test_Detail

- TblScreen

- TblWater

- TblWWR

- Estimated Recurrence Time: As necessary

This section describes the methodology, procedures and scripts necessary to convert the MOE Water Well Database (WWDB) to the format necessary for import into the YPDT-CAMC Database (YCDB). The details provided are particular to the structure and state of the WWDB as of 2017-09, the date at which the updated database was made available to the YPDT-CAMC (additional notes may be included for characteristics/changes in newer versions of the WWDB). This section presupposes that the WWDB has already been incorporated as an SQL Server database. (Note that this can be accomplished through the use of the ‘SQL Server Import and Export Data’ tool; the 32-bit version is recommended in this case.)

Note that only the data tables are listed above. In addition, various look-up tables from both databases are used as part of the conversion process. The process itself is destructive in that modifications are made as necessary to the source tables. As such, a backup of the WWDB should be created before proceeding.

SQL code is available both in this document are also available as an ‘.sql’ file (found within the ‘Appendix - G - Procedures - scripts’ directory; the file names are of the form ‘

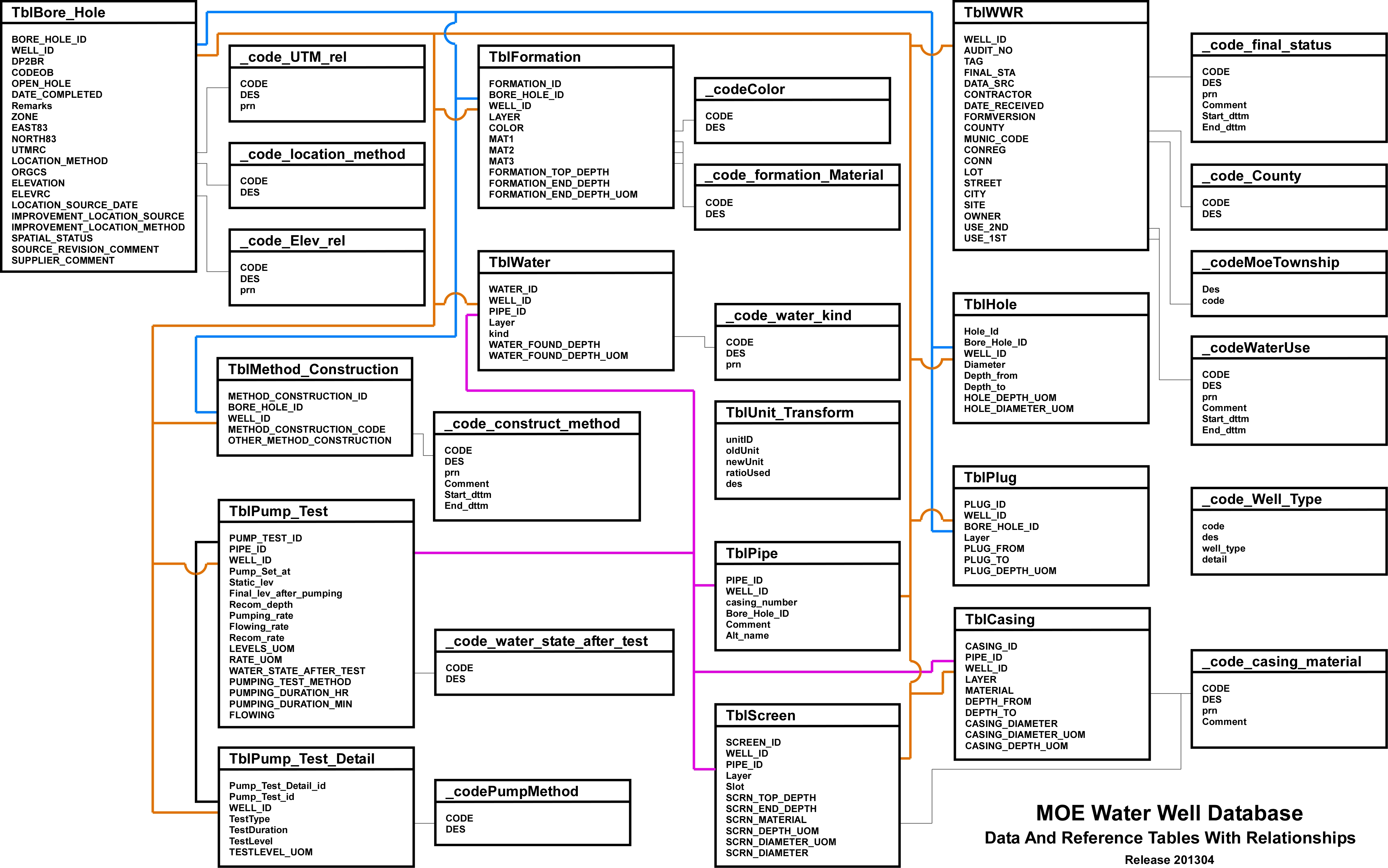

The relationships between the MOE WWDB tables (as of 20170905) is shown.

Figure G.10.1 Relationship between the MOE WWDB source tables

Figure G.10.1 Relationship between the MOE WWDB source tables

G.10.1 Determination of WELL_IDs to be imported

The WELL_ID is the primary key by which missing boreholes (from the YCDB) are determined. Note that this is not the primary key used to distinguish between boreholes in the WWDB - the BORE_HOLE_ID (variously identified) is used instead, where multiple BORE_HOLE_IDs are associated with a single WELL_ID. The WELL_ID is stored as LOC_ORIGINAL_NAME in D_LOCATION for many locations; both the WELL_ID and the BORE_HOLE_ID are stored as aliases in D_LOCATION_ALIAS, linked by the LOC_ID. Inclusion of both identifiers allows back-checking of information (to the WWDB).

Approximately 768,401WELL_IDs are present in ‘TblBore_Hole’. In addition to the data already present in the YCDB, we’re also using a NULL value in any of ZONE, EAST83 or NORTH83 to remove a particular WELL_ID from consideration. The row-counter is present in the case we need to create an on-the-fly relationship to other tables.

Create the look-up table.

select

ZONE

,count(*) as [rowcount]

,case

when ZONE=15 then 7

when ZONE=16 then 8

when ZONE=17 then 4

when ZONE=18 then 5

else null -- the remainder of the zones should be invalid

end

as [LOC_COORD_OUOM_CODE]

FROM

MOE_20170905.[dbo].[TblBore_Hole] as tbh

group by

ZONE

Script: G_10_01_01_ZONE.sql

Extract the WELL_IDs.

select

distinct(missing.WELL_ID)

--,ROW_NUMBER() over (order by missing.WELL_ID) as [rnum]

,cast(null as int) as well_id_rnum

into MOE_20220328.dbo.YC_20220328_WELL_ID_AVAIL

from

(

select

tbh.WELL_ID

,v.LOC_ID

,tbh.ZONE

,tbh.EAST83

,tbh.NORTH83

from

MOE_20220328.dbo.TblBore_Hole as tbh

left outer join OAK_20160831_MASTER.dbo.V_SYS_MOE_LOCATIONS as v

on cast(tbh.WELL_ID as int)=v.MOE_WELL_ID

) as missing

inner join MOE_20220328.dbo.YC_20220328_LOC_COORD_OUOM_CODE as yccode

on missing.ZONE=yccode.ZONE

where

missing.LOC_ID is null

and yccode.ZONE is not null

and missing.EAST83 is not null

and missing.NORTH83 is not null

Script: G_10_01_02_WELL_ID.sql

Note that the SQL ‘collate’ (found in previous versions) has been removed. Instead, V_SYS_MOE_LOCATIONS is being substituted for D_LOCATION (to determine what WELL_IDs have been loaded into the database).

Get the coordinates for each of these WELL_IDs, using BORE_HOLE_ID as the primary key. We’ll use this to delimit the locations to only the YPDT-CAMC study area.

select

bh.BORE_HOLE_ID

,bh.WELL_ID

,cast(bh.well_id as int) as MOE_WELL_ID

,bh.ZONE

,bh.EAST83

,bh.NORTH83

into MOE_20220328.dbo.YC_20220328_BORE_HOLE_ID_COORDS

from

MOE_20220328.dbo.TblBore_Hole as bh

inner join MOE_20220328.dbo.YC_20220328_WELL_ID_AVAIL as avail

on bh.WELL_ID=avail.WELL_ID

Script: G_10_01_03_COORDS.sql

These locations should be exported to a GIS and, by UTM Zone, checked as to whether they are within the study area (check for invalid zones and match against the WELL_IDs for correction; locations with obvious coordinate errors are dropped). Note that we are actually using the YPDT-CAMC study area with a 25km buffer zone. Zones 15 and 16 lie outside the YPDT-CAMC area and are not considered; NULL values are no-longer evaluated as if lying within Zone 17 and are excluded (see G_10_01_02_WELL_ID; these should be evaluated separately using county or address information). Two new fields should be added into this table - EAST83_ORIG and NORTH83_ORG - and these should be populated with the original coordinate values only if a conversion is necessary (i.e. if the location lies within Zone 18) while EAST83 and NORTH83 should contain only Zone 17 coordinates.

Those locations that lie within the YPDT-CAMC area should be loaded into the new table YC_20170905_BORE_HOLE_ID_COORDS_YC within the MOE_20180530 database.

Get the list of WELL_IDs that are going to be added to the YCDB.

select

WELL_ID

,cast(null as int) as well_id_rnum

into MOE_20170905.dbo.YC_20170905_YPDT_WELL_ID

from

MOE_20170905.dbo.YC_20170905_BORE_HOLE_ID_COORDS_YC as y

group by

WELL_ID

Script: G_10_01_04_YPDT_WELL_ID.sql

In the previous database (20170905) there were no instances of multiple boreholes assigned to a single well identifier. In the current version (20180530) this is not the case - likely due to the incorporation of data within the YPDT-CAMC study area using a 25km buffer.

G.10.2 Determination of BORE_HOLE_ID characteristics

We’ll use the BORE_HOLE_IDs from YC_20170905_BORE_HOLE_ID_COORDS_YC (the table created and imported from an external GIS) against which to characterize the locations. First, we’ll determine which BORE_HOLE_ID has geology information (from ‘TblFormation’). A row-count has been added in order to create on-the-fly relationships as necessary. In addition, a series of NULL fields are introduced that will be populated at a later stage in the process.

select

y.BORE_HOLE_ID

,y.WELL_ID

,ROW_NUMBER() over (order by y.BORE_HOLE_ID) as [bore_hold_id_rnum]

,cast(null as int) as [LOC_ID]

,cast(null as int) as [BH_ID]

,convert(int,1) as [LOC_MASTER_LOC_ID]

,convert(float,null) as [FM_MAX_DEPTH]

,convert(varchar(50),null) as [FM_MAX_DEPTH_UNITS]

,convert(float,null) as [MOE_MAX_DEPTH]

,convert(varchar(50),null) as [MOE_MAX_DEPTH_UNITS]

,convert(float,null) as [CON_MAX_DEPTH]

,convert(varchar(50),null) as [CON_MAX_DEPTH_UNITS]

,convert(float,null) as [MAX_DEPTH_M]

,cast(null as int) as NOFORMATION

into MOE_20170905.dbo.YC_20170905_BH_ID

from

MOE_20170905.dbo.YC_20170905_BORE_HOLE_ID_COORDS_YC as y

Script: G_10_02_01_BORE_HOLE_ID.sql

As we’re using the BORE_HOLE_ID as the base key for data conversion, we don’t need to check for repeating WELL_IDs (this differs from using the WELL_ID in the previous import scheme as the base key).

Note the use of a ‘1’ value for the LOC_MASTER_LOC_ID field - this is to indicate that these boreholes are the ‘master’ boreholes in the case of multi-borehole locations (i.e. those locations for which the MOE has allowed a single site geology description to be submitted where multiple boreholes were drilled). We’ll update this field based on the absence/presence of formation information. First check that there are not multiple boreholes, by WELL_ID, that contain formation information.

select

t2.WELL_ID

,t2.rcount

from

(

select

y.WELL_ID

,count(*) as rcount

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join

(

select

f.BORE_HOLE_ID

,count(*) as rcount

from

MOE_20170905.dbo.tblFormation as f

inner join MOE_20170905.dbo.YC_20170905_BH_ID as y

on f.BORE_HOLE_ID=y.BORE_HOLE_ID

group by

f.bore_hole_id

) as t

on y.BORE_HOLE_ID=t.BORE_HOLE_ID

group by

y.WELL_ID

) as t2

where

t2.rcount>1

This should return no rows if there is only a single borehole for each WELL_ID that contains formation information (no rows are returned for MOE_20170905). All of these boreholes (i.e. with formation information) can now be considered ‘master’ locations - we’ll temporarily assign the BORE_HOLE_ID to the LOC_MASTER_LOC_ID to specify this.

update MOE_20170905.dbo.YC_20170905_BH_ID

set

LOC_MASTER_LOC_ID=y.BORE_HOLE_ID

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join

(

select

f.BORE_HOLE_ID

,count(*) as rcount

from

MOE_20170905.dbo.tblFormation as f

inner join MOE_20170905.dbo.YC_20170905_BH_ID as y

on f.BORE_HOLE_ID=y.BORE_HOLE_ID

group by

f.bore_hole_id

) as t

on

y.BORE_HOLE_ID=t.BORE_HOLE_ID

There are considered to be ‘master’ locations. Assign the appropriate BORE_HOLE_ID to the remainder (i.e. the BORE_HOLE_ID and LOC_MASTER_LOC_ID will not match in this case); various methodologies for doing so follows.

select

t2.WELL_ID

,t2.rcount

from

(

select

t.WELL_ID

,count(*) as rcount

from

(

select

y.WELL_ID

,y.BORE_HOLE_ID

,y.LOC_MASTER_LOC_ID

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

where

LOC_MASTER_LOC_ID<>1

) as t

group by

t.WELL_ID

) as t2

where

t2.rcount>1

If there are no rows returned (as in the case of 20170905), there are no cluster/grouped wells with formation information. These need to be further evaluated in a subsequent step. We’ll change the ‘1’ values to a ‘null’ for subsequent examination.

update MOE_20170905.dbo.YC_20170905_BH_ID

set

LOC_MASTER_LOC_ID=null

where

LOC_MASTER_LOC_ID=1

Script: G_10_02_02_MASTER_LOCATIONS.sql

There are 5,661 rows without a declared master location - we will now try and assign them. First evaluate those that consist of a single line, only.

Now that we have assigned a set of master locations (with formation information), check if the null LOC_MASTER_LOC_IDs are relatable.

select

t2.WELL_ID

,t3.WELL_ID

from

(

select

t.WELL_ID

,t.rcount

from

(

select

y.WELL_ID

,count(*) as rcount

from

MOE_20180530.dbo.YC_20180530_BH_ID as y

where

LOC_MASTER_LOC_ID is null

group by

y.WELL_ID

) as t

where

t.rcount=1

) as t2

inner join

(

select

y.WELL_ID

from

MOE_20180530.dbo.YC_20180530_BH_ID as y

where

y.BORE_HOLE_ID=y.LOC_MASTER_LOC_ID

group by

y.WELL_ID

) as t3

on

t2.WELL_ID=t3.WELL_ID

If this returns any rows, check and assign the appropriate BORE_HOLE_ID as the LOC_MASTER_LOC_ID for each row (remember that these won’t have any formation information directly).

update MOE_20180530.dbo.YC_20180530_BH_ID

set

LOC_MASTER_LOC_ID= t.LOC_MASTER_LOC_ID

,NOFORMATION=1

from

MOE_20180530.dbo.YC_20180530_BH_ID as y

inner join

(

select

y.WELL_ID

,y.BORE_HOLE_ID

,y.LOC_MASTER_LOC_ID

from

MOE_20180530.dbo.YC_20180530_BH_ID as y

where

y.loc_master_loc_id=y.bore_hole_ID

) as t

on y.well_id=t.well_id

where

y.loc_master_loc_id is null

Now evaluate those that consist of a single line, only (these have no formation information as well).

update MOE_20170905.dbo.YC_20170905_BH_ID

set

LOC_MASTER_LOC_ID=y.BORE_HOLE_ID

,NOFORMATION=1

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join

(

select

t.WELL_ID

,t.rcount

from

(

select

y.WELL_ID

,count(*) as rcount

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

where

LOC_MASTER_LOC_ID is null

group by

y.WELL_ID

) as t

where

t.rcount=1

) as t

on y.WELL_ID=t.WELL_ID

#Script: G_10_02_03_MASTER_LOCATIONS_SINGLE.sql*

For the remainder, those WELL_IDs with no formation info but having multiple BORE_HOLE_IDs, assign the smallest BORE_HOLE_ID as the master identifier (this can be changed at a later date, as necessary; note that this was unnecessary for 20170905 but was required for 20180530).

update MOE_20170905.dbo.YC_20170905_BH_ID

set

LOC_MASTER_LOC_ID=t.BORE_HOLE_ID

,NOFORMATION=1

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join

(

select

y.WELL_ID

,min(BORE_HOLE_ID) as BORE_HOLE_ID

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

where

y.LOC_MASTER_LOC_ID is null

group by

y.WELL_ID

) as t

on y.WELL_ID=t.WELL_ID

Script: G_10_02_04_MASTER_LOCATIONS_MULTIPLE.sql

All LOC_MASTER_LOC_IDs should now have been assigned.

Previously, the LOC_MASTER_LOC_IDs were assigned (for non-formation locations) in the following manner:

- If only one of the boreholes has a depth associated with it (from FM_D_BOREHOLE), that borehole is designated the master.

- If only one of the boreholes has water levels associated with it (either from pumping or measure statics), that borehole is designated the master.

- If only one of the boreholes has any construction details, that borehole is designated the master.

- If none of the boreholes have any further details, the deepest or first LOC_ID is designated the master.

G.10.3 Introduction of a LOC_ID (disabled)

The contents of this section has been moved to later in the process.

G.10.4 Creation of formation D_LOCATION (FM_D_LOCATION)

For creating the import D_LOCATION table, a series of look-up tables should be made equating WWDB values to YCDB values.

Convert the MOE final status code to the YPDT-CAMC status code.

select

wwr.FINAL_STA

,case

when wwr.FINAL_STA is null then 4 -- Unknown to Unknown; this should not be used as we're converting nulls to 0

when wwr.FINAL_STA='0' then 4 -- Unknown to Uknown

when wwr.FINAL_STA='1' then 1 -- Water Supply to Active

when wwr.FINAL_STA='2' then 1 -- Observation to Active

when wwr.FINAL_STA='3' then 1 -- Test Hole to Active

when wwr.FINAL_STA='4' then 1 -- Recharge to Active

when wwr.FINAL_STA='5' then 3 -- Abandoned Supply to Abandoned

when wwr.FINAL_STA='6' then 3 -- Abandoned Quality to Abandoned

when wwr.FINAL_STA='7' then 3 -- Unfinished to Abandoned

when wwr.FINAL_STA='8' then 4 -- Not A Well to Unknown

when wwr.FINAL_STA='9' then 1 -- Dewatering to Active

when wwr.FINAL_STA='A' then 3 -- Abandoned-Other to Abandoned

when wwr.FINAL_STA='B' then 4 -- Replacement Well to Unknown

when wwr.FINAL_STA='C' then 4 -- Alteration to Unknown

when wwr.FINAL_STA='D' then 4 -- Other Status to Unknown

when wwr.FINAL_STA='E' then 17 -- Monitoring and Test Hole to MOE Monitoring and Test Hole

when wwr.FINAL_STA='F' then 18 -- Abandoned Monitoring and Test Hole to MOE Abandoned Monitoring and Test Hole

else -9999

end

as [LOC_STATUS_CODE]

,case

when wwr.FINAL_STA is null then 4 -- Unknown to Unknown; this should not be used as we're converting nulls to 0

when wwr.FINAL_STA='0' then null -- Unknown to Unknown

when wwr.FINAL_STA='1' then 1 -- Water Supply to Active

when wwr.FINAL_STA='2' then 2 -- Observation to Active

when wwr.FINAL_STA='3' then 3 -- Test Hole to Active

when wwr.FINAL_STA='4' then 4 -- Recharge to Active

when wwr.FINAL_STA='5' then 5 -- Abandoned Supply to Abandoned

when wwr.FINAL_STA='6' then 6 -- Abandoned Quality to Abandoned

when wwr.FINAL_STA='7' then 7 -- Unfinished to Abandoned

when wwr.FINAL_STA='8' then 8 -- Not A Well to Unknown

when wwr.FINAL_STA='9' then 9 -- Dewatering to Active

when wwr.FINAL_STA='A' then 10 -- Abandoned-Other to Abandoned

when wwr.FINAL_STA='B' then 11 -- Replacement Well to Unknown

when wwr.FINAL_STA='C' then 12 -- Alteration to Unknown

when wwr.FINAL_STA='D' then 13 -- Other Status to Unknown

when wwr.FINAL_STA='E' then 14 -- Abandoned Monitoring and Test Hole to MOE Abandoned Monitoring and Test Hole

when wwr.FINAL_STA='F' then 15 -- Abandoned Monitoring and Test Hole to MOE Abandoned Monitoring and Test Hole

else -9999

end

as [BH_STATUS_CODE]

into

MOE_20170905.dbo.YC_20170905_FINAL_STATUS

from

MOE_20170905.dbo.TblWWR as wwr

group by

FINAL_STA

order by

FINAL_STA

For null values in ‘TblWWR’, assign them a ‘0’ value to match the look-up table.

update MOE_20170905.[dbo].[TblWWR]

set

FINAL_STA=0

where

FINAL_STA is null

Script: G_10_04_01_FINAL_STATUS.sql

The look-up table for the MOE first and second use should not contain any NULLs (as they cannot be used as a key); change these values to ‘0’.

update MOE_20170905.dbo.TblWWR

set

USE_1ST=0

where

USE_1ST is null

update MOE_20170905.dbo.TblWWR

set

USE_2ND=0

where

USE_2ND is null

Create the MOE use look-up table (both the USE_1ST and USE_2ND are examined; the SQL code would be otherwise equivalent after the change in the field name).

select

wwr.USE_1ST

,case

when wwr.USE_1ST is null then 0 -- Unknown

when wwr.USE_1ST='0' then 0 -- Unknown

when wwr.USE_1ST='A' then 10 -- OTHER

when wwr.USE_1ST='B' then 11 -- TEST HOLE

when wwr.USE_1ST='C' then 12 -- DEWATERING

when wwr.USE_1ST='D' then 13 -- MONITORING

when wwr.USE_1ST='E' then 14 -- Monitoring and Test Hole

else wwr.USE_1ST

end

as [MOE_USE]

into

MOE_20170905.dbo.YC_20170905_MOE_USE

from

MOE_20170905.dbo.TblWWR as wwr

group by

USE_1ST

order by

USE_1ST

Script: G_10_04_02_MOE_USE.sql

We’ll now extract D_LOCATION equivalent information from the WWDB tables. Note that starting with the 20160531 database, the BORE_HOLE_ID is being used to differentiate between wells (instead of the WELL_ID as previously applied); in this case, the WELL_ID may be applied as the LOC_ORIGINAL_NAME in multiple cases. The LOC_MASTER_LOC_ID should/can be used to determine the ‘master’ LOC_ID - i.e. the WELL_ID/BORE_HOLE_ID combination linked to the geology at a particular location. In most cases, the LOC_ID and LOC_MASTER_LOC_ID will be same value; for those locations where a MOE ‘multiple-borehole’ submittal was done (i.e. multiple locations tied to single description of the geology) the LOC_ID will differ from the LOC_MASTER_LOC_ID. In addition, a new DATA_ID must be specified (and included in D_DATA_SOURCE) for each MOE import date. For example, the DATA_ID of ‘519’ refers to ‘MOE WWR Database - 201700905’.

select

y.BORE_HOLE_ID as LOC_ID

,cast(bh.WELL_ID as varchar(255)) as [LOC_NAME]

,cast('MOE Well 20220502 - Name Witheld by MOE' as varchar(255)) as [LOC_NAME_ALT1]

,cast(1 as int) as [LOC_TYPE_CODE]

,cast(bh.WELL_ID as varchar(255)) as [LOC_ORIGINAL_NAME]

,y.[LOC_MASTER_LOC_ID]

,yccoords.[EAST83] as [LOC_COORD_EASTING]

,yccoords.[NORTH83] as [LOC_COORD_NORTHING]

,yccoords.east83_orig as LOC_COORD_EASTING_OUOM

,yccoords.north83_orig as LOC_COORD_NORTHING_OUOM

,case

when yccoords.zone= 17 then 4

else 5

end as LOC_COORD_OUOM_CODE

,cast(wwr.COUNTY as int) as [LOC_COUNTY_CODE]

,cast(wwr.MUNIC_CODE as int) as [LOC_TOWNSHIP_CODE]

,ycfs.LOC_STATUS_CODE

,bh.DATE_COMPLETED as [LOC_START_DATE]

,cast(1 as int) as [SITE_ID]

,cast(1 as int) as [LOC_CONFIDENTIALITY_CODE]

,cast(wwr.DATA_SRC as int) as [LOC_DATA_SOURCE_CODE]

,cast(wwr.CONN as varchar(50)) as [LOC_CON]

,cast(wwr.LOT as varchar(50)) as [LOC_LOT]

,cast(RTRIM(LTRIM(wwr.STREET)) as varchar(255)) as [LOC_ADDRESS_INFO1]

,cast(RTRIM(LTRIM(wwr.CITY)) as varchar(255)) as [LOC_ADDRESS_CTY]

,ycmoeu1.MOE_USE as [LOC_MOE_USE_1ST_CODE]

,ycmoeu2.MOE_USE as [LOC_MOE_USE_2ND_CODE]

,524 as DATA_ID

into MOE_20220328.dbo.M_D_LOCATION

from

MOE_20220328.dbo.YC_20220328_BH_ID as y

inner join MOE_20220328.dbo.TblBore_Hole as bh

on y.BORE_HOLE_ID=bh.BORE_HOLE_ID

left outer join MOE_20220328.dbo.TblWWR as wwr

on bh.WELL_ID=wwr.WELL_ID

left outer join MOE_20220328.dbo.YC_20220328_LOC_COORD_OUOM_CODE as yccode

on bh.ZONE=yccode.ZONE

left outer join MOE_20220328.dbo.YC_20220328_FINAL_STATUS as ycfs

on wwr.FINAL_STA=ycfs.FINAL_STA

inner join MOE_20220328.dbo.YC_20220328_MOE_USE as ycmoeu1

on wwr.USE_1ST=ycmoeu1.USE_1ST

inner join MOE_20220328.dbo.YC_20220328_MOE_USE as ycmoeu2

on wwr.USE_2ND=ycmoeu2.USE_1ST

inner join MOE_20220328.dbo.YC_20220328_BORE_HOLE_ID_COORDS_YC as yccoords

on y.BORE_HOLE_ID=yccoords.BORE_HOLE_ID

Check the LOC_ADDRESS field for zero-length values (and null them).

update MOE_20170905.dbo.M_D_LOCATION

set

LOC_ADDRESS_INFO1=null

from

MOE_20170905.dbo.M_D_LOCATION as m

where

len(LOC_ADDRESS_INFO1)=0

Script: G_10_04_03_M_D_LOCATION.sql

G.10.5 Determining elevations

We’ll now use the source of YC_20180530_BORE_HOLE_ID_COORDS_YC (i.e. the external GIS) to determine the elevation of each location from the relevant DEMs. We are not including any automated geocoding here (as we did in the previous conversion instructions) as this introduced a number of erroneous results.

The resultant table should be called YC_20160531_BORE_HOLE_ID_ELEVS and contain the following fields.

- BORE_HOLE_ID

- DEM_MNR

- DEM_SRTM

For those locations falling (just) outside of the study area, their MNR elevations will be tagged with a ‘-9999’ value. Refer to the following script (not shown) for details.

Script: G_10_05_ELEVATIONS.sql

G.10.6 Location aliases

Multiple aliases for each location are present within the WWDB. These include the BORE_HOLE_ID (where the WELL_ID is found in LOC_ORIGINAL_NAME), the WELL_ID, the ‘MOE Tag Number’ and the ‘MOE Audit Number’.

As of 2022-05-02, we’ll manually add a MOE_WELL_ID to the pertinent tables to use for comparison instead of relying upon the character based WELL_ID (where we can experience collation issues). This should be incorporated earlier in the import process.

Assemble the alias information for BORE_HOLE_ID.

select

y.BORE_HOLE_ID as LOC_ID

,cast(y.BORE_HOLE_ID as varchar(255)) as LOC_NAME_ALIAS

,cast(3 as int) as [LOC_ALIAS_TYPE_CODE]

,cast(null as int) as SYS_RECORD_ID

into MOE_20170905.dbo.M_D_LOCATION_ALIAS

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

Add the information for the ‘MOE Tag Number’.

insert into MOE_20170905.dbo.M_D_LOCATION_ALIAS

(LOC_ID,LOC_NAME_ALIAS,LOC_ALIAS_TYPE_CODE)

select

y.BORE_HOLE_ID as LOC_ID

,cast(m.TAG as varchar(255)) as LOC_NAME_ALIAS

,cast(1 as int) as [LOC_ALIAS_TYPE_CODE]

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join MOE_20170905.dbo.TblWWR as m

on y.MOE_WELL_ID=m.MOE_WELL_ID

where

m.TAG is not null

Add the information for the ‘MOE Audit Number’.

insert into MOE_20170905.dbo.M_D_LOCATION_ALIAS

(LOC_ID,LOC_NAME_ALIAS,LOC_ALIAS_TYPE_CODE)

select

y.BORE_HOLE_ID as LOC_ID

,cast(m.AUDIT_NO as varchar(255)) as LOC_NAME_ALIAS

,cast(2 as int) as [LOC_ALIAS_TYPE_CODE]

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join MOE_20170905.dbo.TblWWR as m

on y.MOE_WELL_ID=m.MOE_WELL_ID

where

m.AUDIT_NO is not null

Add the information for the WELL_ID.

insert into MOE_20170905.dbo.M_D_LOCATION_ALIAS

(LOC_ID,LOC_NAME_ALIAS,LOC_ALIAS_TYPE_CODE)

select

y.LOC_ID

,cast(y.LOC_ORIGINAL_NAME as varchar(255)) as LOC_NAME_ALIAS

,cast(4 as int) as [LOC_ALIAS_TYPE_CODE]

from

MOE_20170905.dbo.M_D_LOCATION as y

Script: G_10_06_01_FM_D_LOC_ALIAS.sql

G.10.7 Location QA

The QA codes between the WWDB and YCDB match with the exceptions that a NULL value from the WWDB needs to be changed to a value of ‘9’ for the YCDB. Default the QA_ELEV_CONFIDENCE_CODE to ‘10’ (DEM) unless the ELEVRC (from the MOE) has a value of ‘1’.

select

y.BORE_HOLE_ID as LOC_ID

,case

when m.UTMRC is null then 9

else m.UTMRC

end

as [QA_COORD_CONFIDENCE_CODE]

,case

when m.UTMRC is null then 9

else m.UTMRC

end

as [QA_COORD_CONFIDENCE_CODE_ORIG]

,m.[LOCATION_METHOD] as [QA_COORD_METHOD]

,case

when m.ELEVRC=1 then 1

else 10

end as [QA_ELEV_CONFIDENCE_CODE]

,m.ELEVRC as [QA_ELEV_CONFIDENCE_CODE_ORIG]

into MOE_20170905.dbo.M_D_LOCATION_QA

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join MOE_20170905.dbo.TblBore_Hole as m

on y.BORE_HOLE_ID=m.BORE_HOLE_ID

Script: G_10_07_01_M_D_LOC_QA.sql

G.10.8 Location elevation

The DEM elevations using the coordinates in the M_D_LOCATION table have been determined externally to this database-translation scheme and are present in YC_20160531_BORE_HOLE_ID_ELEVS (as found in Section G.10.5). The MOE elevation is being pulled from ‘TblBore_Hole - ELEVATION’ and is assumed to be expressed in ‘masl’. Note that if the QA_COORD_CONFIDENCE CODE for a location has a value of ‘1’, the final assigned elevation would be this. Otherwise, the value from ‘MNR DEM v2’ (i.e. using the field ‘dem_mnr’) or ‘SRTM DEM v4.1’ (where the location appears outside of the ORMGP study area; i.e. using the field ‘dem_srtm’)

We’ll populate M_D_LOCATION_SPATIAL_HIST with the original elevation (from the MOE) first, where present.

select

y.BORE_HOLE_ID as LOC_ID

,cast(4 as int) as LOC_COORD_HIST_CODE

,cast( '2021-01-19' as datetime ) as LOC_COORD_DATE

,ycoord.east83 as X

,ycoord.north83 as Y

,cast( 26917 as int ) as EPSG_CODE

,ycoord.east83_orig as X_OUOM

,ycoord.north83_orig as Y_OUOM

,cast( ( case when ycoord.zone_orig=17 then 26917 else 26918 end ) as int ) as EPSG_CODE_OUOM

,dlqa.qa_coord_confidence_code as QA_COORD_CODE

,cast( 523 as int ) as LOC_COORD_DATA_ID

,cast( ( case when m.location_method is not null and len(m.location_method)>0 then m.location_method else null end ) as varchar(255) ) as LOC_COORD_METHOD

,cast( ( case when m.elevation is not null then 2 else null end ) as int ) as LOC_ELEV_CODE

,cast( ( case when m.elevation is not null then '2021-01-19' else null end ) as datetime ) as LOC_ELEV_DATE

,cast(m.ELEVATION as float) as LOC_ELEV

,cast( ( case when m.elevation is not null then 6 else null end ) as int ) as LOC_ELEV_UNIT_CODE

,cast(m.ELEVATION as float) as LOC_ELEV_OUOM

,cast( ( case when m.elevation is not null then 'masl' else null end ) as varchar(50) ) as LOC_ELEV_UNIT_OUOM

,cast( null as int ) as QA_ELEV_CODE

,cast( ( case when m.elevation is not null then 523 else null end ) as int ) as LOC_ELEV_DATA_ID

,cast( ( case when m.elevrc is not null and len(m.elevrc)>0 then m.elevrc else null end ) as varchar(255) ) as LOC_ELEV_COMMENT

into MO_20210119.dbo.M_D_LOCATION_SPATIAL_HIST

from

MOE_20210119.dbo.YC_20210119_BH_ID as y

inner join MOE_20210119.dbo.TblBore_Hole as m

on y.BORE_HOLE_ID=m.BORE_HOLE_ID

inner join MOE_20210119.dbo.YC_20210119_BORE_HOLE_ID_COORDS_YC as ycoord

on y.bore_hole_id=ycoord.bore_hole_id

inner join MOE_20210119.dbo.M_D_LOCATION_QA as dlqa

on y.bore_hole_id=dlqa.loc_id

Then the MNR DEM (v2) or SRTM DEM (v4.1); the latter is used if the first is tagged with a ‘-9999’ value.

insert into MOE_20210119.dbo.M_D_LOCATION_SPATIAL_HIST

(

LOC_ID

,LOC_COORD_HIST_CODE

,LOC_COORD_DATE

,X

,Y

,EPSG_CODE

,X_OUOM

,Y_OUOM

,EPSG_CODE_OUOM

,QA_COORD_CODE

,LOC_COORD_DATA_ID

,LOC_COORD_METHOD

,LOC_ELEV_CODE

,LOC_ELEV_DATE

,LOC_ELEV

,LOC_ELEV_UNIT_CODE

,LOC_ELEV_OUOM

,LOC_ELEV_UNIT_OUOM

,QA_ELEV_CODE

,LOC_ELEV_DATA_ID

,LOC_ELEV_COMMENT

)

select

y.BORE_HOLE_ID as LOC_ID

,cast(4 as int) as LOC_COORD_HIST_CODE

,cast( '2021-01-19' as datetime ) as LOC_COORD_DATE

,ycoord.east83 as X

,ycoord.north83 as Y

,cast( 26917 as int ) as EPSG_CODE

,ycoord.east83_orig as X_OUOM

,ycoord.north83_orig as Y_OUOM

,cast( ( case when ycoord.zone_orig=17 then 26917 else 26918 end ) as int ) as EPSG_CODE_OUOM

,dlqa.qa_coord_confidence_code as QA_COORD_CODE

,cast( 523 as int ) as LOC_COORD_DATA_ID

,cast( ( case when m.location_method is not null and len(m.location_method)>0 then m.location_method else null end ) as varchar(255) ) as LOC_COORD_METHOD

,cast( ( case when ye.dem_mnr=-9999 then 5 else 3 end ) as int ) as LOC_ELEV_CODE

,cast( '2021-01-19' as datetime ) as LOC_ELEV_DATE

,cast( ( case when ye.dem_mnr=-9999 then ye.dem_srtm else ye.dem_mnr end ) as float ) as LOC_ELEV

,cast( 6 as int ) as LOC_ELEV_UNIT_CODE

,cast( ( case when ye.dem_mnr=-9999 then ye.dem_srtm else ye.dem_mnr end ) as float ) as LOC_ELEV_OUOM

,cast( 'masl' as varchar(50) ) as LOC_ELEV_UNIT_OUOM

,cast( 10 as int ) as QA_ELEV_CODE

,cast( null as int ) as LOC_ELEV_DATA_ID

,cast( null as varchar(255) ) as LOC_ELEV_COMMENT

,cast( null as varchar(255) ) as LOC_ELEV_COMMENT

from

MOE_20210119.dbo.YC_20210119_BH_ID as y

inner join MOE_20210119.dbo.YC_20210119_BORE_HOLE_ID_ELEVS as ye

on y.bore_hole_id=ye.bore_hole_id

inner join MOE_20210119.dbo.TblBore_Hole as m

on y.BORE_HOLE_ID=m.BORE_HOLE_ID

inner join MOE_20210119.dbo.YC_20210119_BORE_HOLE_ID_COORDS_YC as ycoord

on y.bore_hole_id=ycoord.bore_hole_id

inner join MOE_20210119.dbo.M_D_LOCATION_QA as dlqa

on y.bore_hole_id=dlqa.loc_id

Script: G_10_08_01_M_D_LOC_ELEV.sql

Note that the corresponding table - D_LOCATION_SPATIAL - will be created at a later step (after the D_LOCATION_SPATIAL_HIST has been imported; the required SPAT_ID will be automatically generated at that time).

G.10.09 Borehole information

As part of the process, a driller identifier (BH_DRILLER_CODE) must be present in R_BH_DRILLER_CODE. Potentially, the WWDB could add new driller identifiers - these will need to be accounted for before the M_D_BOREHOLE table is created.

Determine if there are any drillers not listed in R_BH_DRILLER_CODE

select

m.CONTRACTOR

from

MOE_20170905.dbo.TblWWR as m

where

m.CONTRACTOR collate database_default

not in

(

select bh_driller_alt_code collate database_default

from OAK_20160831_MASTER.dbo.R_BH_DRILLER_CODE

)

Script: G_10_09_01_DRILLER_CODE.sql

If any CONTRACTOR codes/names are returned, these need to be added into the R_BH_DRILLER_CODE (note that there were no new driller codes found for this version of the WWDB).

A comparison table is required for matching the MOE drill method codes to the YPDT-CAMC drill method codes. In some cases, the codes are not specified (or not specified correctly). As such, there is some effort required for manipulating the MOE drill method codes so that they will match directly (in addition, the text field OTHER_METHOD_CONSTRUCTION in the WWDB is accessed). Refer to the following script reference.

Script: G_10_09_02_MOD_DRILL_METH.sql

We can now map the MOE (modified) drill methods to the YPDT-CAMC drill method codes on a case-by-case (by BORE_HOLE_ID) basis.

select

y.BORE_HOLE_ID

,m.METHOD_CONSTRUCTION_CODE

,case

when m.METHOD_CONSTRUCTION_CODE is null then 0

when m.METHOD_CONSTRUCTION_CODE = '0' then 0 -- Unknown

when m.METHOD_CONSTRUCTION_CODE = '1' then 1 -- Cable-tool

when m.METHOD_CONSTRUCTION_CODE = '2' then 2 -- Rotary Conventional

when m.METHOD_CONSTRUCTION_CODE = '3' then 3 -- Rotary Reverse

when m.METHOD_CONSTRUCTION_CODE = '4' then 4 -- Rotary Air

when m.METHOD_CONSTRUCTION_CODE = '5' then 5 -- Air Percussion

when m.METHOD_CONSTRUCTION_CODE = '6' then 6 -- Boring

when m.METHOD_CONSTRUCTION_CODE = '7' then 7 -- Diamond

when m.METHOD_CONSTRUCTION_CODE = '8' then 8 -- Jetting

when m.METHOD_CONSTRUCTION_CODE = '9' then 9 -- Driving

when m.METHOD_CONSTRUCTION_CODE = 'A' then 10 -- Hand auger digging

when m.METHOD_CONSTRUCTION_CODE = 'B' then 0 -- Other Method

when m.METHOD_CONSTRUCTION_CODE = 'C' then 0 -- TBD

when m.METHOD_CONSTRUCTION_CODE = 'D' then 9 -- Direct Push

when m.METHOD_CONSTRUCTION_CODE = 'E' then 12 -- Auger (solid stem auger)

when m.METHOD_CONSTRUCTION_CODE = 'F' then 13 -- Hollow stem auger

when m.METHOD_CONSTRUCTION_CODE = 'G' then 12 -- Solid stem auger

when m.METHOD_CONSTRUCTION_CODE = 'H' then 16 -- Geoprobe

when m.METHOD_CONSTRUCTION_CODE = 'I' then 43 -- Sonic

when m.METHOD_CONSTRUCTION_CODE = 'Y' then 18 -- ADDED: a YC code only - Pionjar

when m.METHOD_CONSTRUCTION_CODE = 'Z' then 46 -- ADDED: a YC code only - Rotary (dual)

else 0

end

as BH_DRILL_METHOD_CODE

into MOE_20180530.dbo.YC_20180530_DRILL_CODE

from

MOE_20180530.dbo.YC_20180530_BH_ID as y

inner join [MOE_20160531].[dbo].[TblMethod_Construction] as m

on y.BORE_HOLE_ID= m.BORE_HOLE_ID

Script: G_10_09_03_DRILL_METH.sql

We’ll also need to check that a BH_DRILLER_CODE exists for every specified MOE driller. Insert any that are missing into R_BH_DRILLER_CODE. (Note that if we’re not working against the master database, we’ll need to store these values in M_R_BH_DRILLER_CODE to be incorporated later; this code is not shown here.)

insert into [OAK_20160831_MASTER].dbo.R_BH_DRILLER_CODE

(BH_DRILLER_DESCRIPTION,BH_DRILLER_DESCRIPTION_LONG,BH_DRILLER_ALT_CODE)

select

t.BH_DRILLER_DESCRIPTION

,t.BH_DRILLER_DESCRIPTION_LONG

,t.BH_DRILLER_ALT_CODE

from

(

select

cast('MOE Driller No. ' + cast(moewwr.CONTRACTOR as varchar(255)) as varchar(255)) as BH_DRILLER_DESCRIPTION

,cast('MOE Driller No. ' + cast(moewwr.CONTRACTOR as varchar(255)) as varchar(255)) as BH_DRILLER_DESCRIPTION_LONG

,cast(moewwr.CONTRACTOR as varchar(255)) as BH_DRILLER_ALT_CODE

from

MOE_20210119.dbo.YC_20210119_BH_ID as y

left outer join MOE_20210119.dbo.TblWWR as moewwr

on y.WELL_ID=moewwr.WELL_ID

left outer join

OAK_20160831_MASTER.dbo.R_BH_DRILLER_CODE as rbdc

on moewwr.CONTRACTOR collate database_default=rbdc.BH_DRILLER_ALT_CODE collate database_default

where

rbdc.BH_DRILLER_CODE is null

) as t

group by

t.BH_DRILLER_DESCRIPTION,t.BH_DRILLER_DESCRIPTION_LONG,t.BH_DRILLER_ALT_CODE

Script: G_10_09_04_DRILLER.sql

The M_D_BOREHOLE table can now be assembled. Note that we’re introducing a placeholder (i.e. BH_BOTTOM_OUOM and BH_BOTTOM_UNIT_OUOM) for the borehole depths until we determine the maximum depth (of the borehole) from various methods.

For the 20200721 import, it was found that there a number of drill methods specified for the same borehole (by BORE_HOLE_ID). These additional procedures were translated into text and added to the BH_COMMENT field. This methodology should be standardized before the next import (there was only an ad-hoc development here; refer to the following script file for details).

select

y.BORE_HOLE_ID as BH_ID

,y.BORE_HOLE_ID as LOC_ID

,cast(null as float) as BH_GND_ELEV

,cast(null as float) as BH_GND_ELEV_OUOM

,cast('masl' as varchar(50)) as BH_GND_ELEV_UNIT_OUOM

,cast(null as float) as BH_DEM_GND_ELEV

,cast(null as float) as BH_BOTTOM_ELEV

,cast(null as float) as BH_BOTTOM_DEPTH

,cast(null as float) as BH_BOTTOM_OUOM

,cast('mbgs' as varchar(50)) as BH_BOTTOM_UNIT_OUOM

,ydc.BH_DRILL_METHOD_CODE

,rbdc.BH_DRILLER_CODE as [BH_DRILLER_CODE]

,moebh.DATE_COMPLETED as [BH_DRILL_END_DATE]

,ycfs.BH_STATUS_CODE

,cast(90 as int) as [BH_DIP]

,cast(0 as int) as [BH_AZIMUTH]

,cast(moeh.max_diameter as float) as BH_DIAMETER_OUOM

,cast(moeh.HOLE_DIAMETER_UOM as varchar(50)) as BH_DIAMETER_UNIT_OUOM

,cast(moecwt.[des] as varchar(255)) as MOE_BH_GEOLOGY_CLASS

,rtrim( cast( ydc.BH_COMMENT as varchar(255) ) ) as BH_COMMENT

,row_number() over (order by y.bore_hole_id) as rkey

into MOE_20210119.dbo.M_D_BOREHOLE

from

MOE_20210119.dbo.YC_20210119_BH_ID as y

left outer join MOE_20210119.dbo.YC_20210119_DRILL_CODE as ydc

on y.BORE_HOLE_ID=ydc.BORE_HOLE_ID

left outer join

(

select

moeh.Bore_Hole_ID

,MAX(moeh.Diameter) as [max_diameter]

,moeh.HOLE_DIAMETER_UOM

from

MOE_20210119.dbo.TblHole as moeh

where

moeh.diameter is not null

group by

Bore_Hole_ID,moeh.HOLE_DIAMETER_UOM

) as moeh

on y.BORE_HOLE_ID=moeh.Bore_Hole_ID

left outer join MOE_20210119.dbo.TblWWR as moewwr

on y.WELL_ID=moewwr.WELL_ID

left outer join MOE_20210119.dbo.YC_20210119_FINAL_STATUS as ycfs

on moewwr.FINAL_STA=ycfs.FINAL_STA

inner join MOE_20210119.dbo.TblBore_Hole as moebh

on y.BORE_HOLE_ID=moebh.BORE_HOLE_ID

left outer join MOE_20210119.dbo._code_Well_Type as moecwt

on moebh.CODEOB=moecwt.code

left outer join OAK_20160831_MASTER.dbo.R_BH_DRILLER_CODE as rbdc

on moewwr.CONTRACTOR collate database_default=rbdc.BH_DRILLER_ALT_CODE collate database_default

In order to account for any multiple drill methods used for a particular location we’ll first create a view.

create view V_DBORE_DRILL_CODES as

select

dbore.rkey

,t.min_rkey

,t.max_rkey

,t.rcount

from

(

select

loc_id

,min(rkey) as min_rkey

,max(rkey) as max_rkey

,count(*) as rcount

from

MOE_20210119.dbo.M_D_BOREHOLE

group by

loc_id

) as t

inner join MOE_20210119.dbo.M_D_BOREHOLE as dbore

on t.loc_id=dbore.loc_id

where

t.rcount>1

and dbore.rkey=t.max_rkey

We can then use this as a base to create a series of temporary tables containing the additional drilling methods.

select

dbore.BH_ID

,dbore.LOC_ID

,dbore.BH_DRILL_METHOD_CODE

,dbore.rkey

--into MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_1

--into MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_2

--into MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_3

--into MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_4

from

MOE_20210119.dbo.M_D_BOREHOLE as dbore

inner join MOE_20210119.dbo.V_DBORE_DRILL_CODES as v

on dbore.rkey=v.rkey

After each table is created, we’ll remove the particular record from M_D_BOREHOLE (until it matches the number of rows in M_D_LOCATION).

delete from MOE_20210119.dbo.M_D_BOREHOLE

where rkey in

(

select

rkey

from

--MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_1

--MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_2

--MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_3

--MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_4

)

These additional tables can then be used to generated the text describing these methods which can be added to the BH_COMMENT field.

update MOE_20210119.dbo.M_D_BOREHOLE

set

BH_COMMENT=

case

when bh_comment is null then t.to_add

else bh_comment + '; ' + t.to_add

end

from

MOE_20210119.dbo.M_D_BOREHOLE as moe

inner join

(

select

dbore.LOC_ID

,'Addn drill methods: '+ r1.bh_drill_method_description +

case

when d2.loc_id is not null then

case

when d3.loc_id is not null then

'; ' + r2.bh_drill_method_description + '; ' + r3.bh_drill_method_description

else '; ' + r2.bh_drill_method_description

end

else ''

end as to_add

from

MOE_20210119.dbo.M_D_BOREHOLE as dbore

inner join MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_1 as d1

on dbore.loc_id=d1.loc_id

inner join OAK_20160831_MASTER.dbo.R_BH_DRILL_METHOD_CODE as r1

on d1.bh_drill_method_code=r1.bh_drill_method_code

left outer join MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_2 as d2

on dbore.loc_id=d2.loc_id

left outer join OAK_20160831_MASTER.dbo.R_BH_DRILL_METHOD_CODE as r2

on d2.bh_drill_method_code=r2.bh_drill_method_code

left outer join MOE_20210119.dbo.YC_20210119_DBORE_DRILL_CODES_3 as d3

on dbore.loc_id=d3.loc_id

left outer join OAK_20160831_MASTER.dbo.R_BH_DRILL_METHOD_CODE as r3

on d3.bh_drill_method_code=r3.bh_drill_method_code

) as t

on moe.loc_id=t.loc_id

Note that these scripts will be modified depending upon the maximum number of drilling methods specified for any particular location.

Script: G_10_09_05_M_D_BOREHOLE.sql

G.10.10 Borehole construction information

A temporary borehole construction table is first setup allowing the various construction elements to be incorporated. Once this is done, a random SYS_RECORD_ID can be added to the table (using a row-count relationship).

The possible construction elements includes both casing and plug information. As the casing material list is limited, a ‘CASE ? END’ statement will be used instead of a look-up table. Assemble the casing information (at least one column must have information before the row is included).

select

-- note that we're using BORE_HOLE_ID as a temporary BH_ID

y.BORE_HOLE_ID as BH_ID

,case

when moec.MATERIAL is null then 10 -- unknown

when moec.MATERIAL = 1 then 21 -- steel casing

when moec.MATERIAL = 2 then 16 -- galvanized

when moec.MATERIAL = 3 then 23 -- concrete

when moec.MATERIAL = 4 then 24 -- open hole

when moec.MATERIAL = 5 then 25 -- plastic

when moec.MATERIAL = 6 then 32 -- fibreglass

when moec.MATERIAL = 7 then 10 -- unknown/other

when moec.MATERIAL = 8 then 52 -- stainless steel

else -9999

end

as [CON_SUBTYPE_CODE]

,moec.DEPTH_FROM as [CON_TOP_OUOM]

,moec.DEPTH_TO as [CON_BOT_OUOM]

,moec.CASING_DEPTH_UOM as [CON_UNIT_OUOM]

,moec.CASING_DIAMETER as [CON_DIAMETER_OUOM]

,moec.CASING_DIAMETER_UOM as [CON_DIAMETER_UNIT_OUOM]

,convert(varchar(255),null) as CON_COMMENT

from

MOE_20200721.dbo.YC_20200721_BH_ID as y

inner join MOE_20200721.dbo.TblPipe as moep

on y.BORE_HOLE_ID=moep.Bore_Hole_ID

inner join MOE_20200721.dbo.TblCasing as moec

on moep.PIPE_ID=moec.PIPE_ID

where

not

(

moec.DEPTH_TO is null

and moec.CASING_DEPTH_UOM is null

and moec.CASING_DIAMETER is null

and moec.CASING_DIAMETER_UOM is null

)

Assemble the plug information.

insert into MOE_20170905.dbo.YC_20170905_DBHCONS

(BH_ID,CON_SUBTYPE_CODE,CON_TOP_OUOM,CON_BOT_OUOM,CON_UNIT_OUOM)

select

ycb.BORE_HOLE_ID as BH_ID

,29 as CON_SUBTYPE_CODE

,moep.PLUG_FROM as [CON_TOP_OUOM]

,moep.PLUG_TO as [CON_BOT_OUOM]

,moep.PLUG_DEPTH_UOM as [CON_UNIT_OUOM]

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join MOE_20170905.dbo.TblPlug as moep

on ycb.BORE_HOLE_ID=moep.BORE_HOLE_ID

where

not

(

moep.PLUG_FROM is null

and moep.PLUG_TO is null

and moep.PLUG_DEPTH_UOM is null

)

Note that as of v20220328, the default CON_SUBTYPE_CODE has been changed from ‘31’ to ‘29’. The CON_TOP_OUOM should always be less than the CON_BOT_OUOM values. Check this and correct as necessary (not shown).

Script: G_10_10_01_DBHCONS.sql

A series of SYS_RECORD_IDs are now created for the records in the YC_20160531_DBHCONS table (remember that SYS_RECORD_ID is used to create a primary key for a table but cannot be used to create relationships between tables). There will be one SYS_RECORD_ID for each row. Here, though, we’ll just implement a counter (which will function as a temporary value). When importing into the master database, we’ll replace this counter value with an actual random value.

SELECT

[BH_ID]

,[CON_SUBTYPE_CODE]

,[CON_TOP_OUOM]

,[CON_BOT_OUOM]

,[CON_UNIT_OUOM]

,[CON_DIAMETER_OUOM]

,[CON_DIAMETER_UNIT_OUOM]

,[CON_COMMENT]

,ROW_NUMBER() over (order by y.BH_ID) as SYS_RECORD_ID

into MOE_20170905.dbo.M_D_BOREHOLE_CONSTRUCTION

FROM

MOE_20170905.[dbo].[YC_20170905_DBHCONS] as y

Script: G_10_10_02_M_D_BORE_CONS.sql

G.10.11 Location primary and secondary purposes

The recorded MOE usage codes (i.e. LOC_MOE_USE_1ST_CODE and LOC_MOE_USE_2ND_CODE as found in the M_D_LOCATION table) are used, in conjunction (in some cases) with the BH_STATUS_CODE to assign primary and secondary usages to each borehole. Refer to Figure G.10.11.1 and the SQL code for assignement logic.

Table G.10.11.1 Primary and Secondary Purpose assignment.

Due to its excessive length, this code is only found in the following script file. Note that the script(s) may need to be run more than once in the case that updates to the assignment tables (above) need to be made (not shown).

Script: G_10_11_01_M_D_LOC_PURP.sql

G.10.12 Geology feature information (water found)

The D_GEOLOGY_FEATURE table (for information from the WWDB) only contains the ‘Water Found’ values (including the kind and depths; the rows without depths are still incorporated as placeholders, for later editing). Create the table and include a temporary count for the SYS_RECORD_ID value.

select

y.BORE_HOLE_ID as LOC_ID

,case

when moew.kind is null or moew.kind=0 then null -- not specified

else moew.kind -- matches YC codes

end

as [FEATURE_CODE]

,'Water Found' as [FEATURE_DESCRIPTION]

,moew.WATER_FOUND_DEPTH as [FEATURE_TOP_OUOM]

,moew.WATER_FOUND_DEPTH_UOM as [FEATURE_UNIT_OUOM]

,ROW_NUMBER() over (order by y.LOC_ID) as [SYS_RECORD_ID]

into MOE_20170905.dbo.M_D_GEOLOGY_FEATURE

from

MOE_20170905.dbo.YC_20170905_BH_ID as y

inner join MOE_20170905.dbo.TblPipe as moep

on y.BORE_HOLE_ID=moep.Bore_Hole_ID

inner join MOE_20170905.[dbo].[TblWater] as moew

on moep.PIPE_ID=moew.PIPE_ID

Script: G_10_12_01_M_D_GEOL_FEAT.sql

G.10.13 Geology

The geology layer look-up codes are equivalent between the WWDB and YCDB with the exception of code ‘27’ (i.e. ‘Other’). This is to be matched to code ‘0’ (i.e. ‘Unknown’) for each of the material fields (MAT1 through MAT3). The process is not described here - refer to the following script.

Script: G_10_13_01_GL_OTHER.sql

All depth units from the WWDB must be in either ‘ft’ or ‘m’; in some cases, ‘inch’ or ‘cm’ is used instead. These should be changed - the process is not described here - refer to the following script.

Script: G_10_13_02_GL_UNITS.sql

The geology table (i.e. equivalent to D_GEOLOGY_LAYER) can now be created. Note that a few modifications are made.

- If all material codes are NULL, MAT1 is assigned a ‘0’

- If MAT1 is null but MAT2 is not, make MAT1=MAT2 then make MAT2 NULL

- If MAT1 and MAT2 is null but MAT3 is not, make MAT1=MAT3 and NULL MAT2 and MAT3

- If any of these conditions are met, an appropriate comment is added, otherwise NULL

Review the script itself for details.

select

-- note that we're substituting the BORE_HOLE_ID for LOC_ID

ycb.BORE_HOLE_ID as LOC_ID

,case

when moef.COLOR is null or moef.COLOR=0 then null

else moef.COLOR

end

as [GEOL_MAT_COLOUR_CODE]

,moef.FORMATION_TOP_DEPTH as GEOL_TOP_OUOM

,moef.FORMATION_END_DEPTH as GEOL_BOT_OUOM

,moef.FORMATION_END_DEPTH_UOM as GEOL_UNIT_OUOM

,moef.LAYER as GEOL_MOE_LAYER

,case

-- check if all mat fields are null

when moef.MAT1 is null and moef.MAT2 is null and moef.MAT3 is null then 0

-- if mat1 is null but mat2 is not, make mat1=mat2

when moef.MAT1 is null and moef.MAT2 is not null then moef.MAT2

-- if mat1 and mat2 is null but mat3 is not, make mat1=mat3

when moef.MAT1 is null and moef.MAT2 is null and moef.MAT3 is not null then moef.MAT3

else moef.MAT1

end as GEOL_MAT1_CODE

,case

-- if all mat fields are null, leave mat2 as is

-- if mat1 is null, mat2 has been moved to mat1, return null

-- we won't move mat3 to mat2

when moef.MAT1 is null and moef.MAT2 is not null then null

else moef.MAT2

end as GEOL_MAT2_CODE

,case

-- if mat1 and mat2 is null but mat3 is not, make mat1=mat3

when moef.MAT1 is null and moef.MAT2 is null and moef.MAT3 is not null then null

else moef.MAT3

end as GEOL_MAT3_CODE

-- include some comments if we've messed about with the mat codes

,case

when moef.MAT1 is null and moef.MAT2 is null and moef.MAT3 is null then 'No material, assigned unknown'

when moef.MAT1 is null and moef.MAT2 is not null then 'No mat1, assigned mat2 to mat1'

when moef.MAT1 is null and moef.MAT2 is null and moef.MAT3 is not null then 'No mat1 or mat2, assigned mat3 to mat1'

else null

end as GEOL_COMMENT

,ROW_NUMBER() over (order by ycb.LOC_ID) as SYS_RECORD_ID

into MOE_20170905.dbo.M_D_GEOLOGY_LAYER

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join MOE_20170905.dbo.TblFormation as moef

on ycb.BORE_HOLE_ID=moef.BORE_HOLE_ID

Script: G_10_13_03_M_D_GEOL_LAY.sql

G.10.14 Determine maximum depth

Maximum depth for each borehole needs to be determined - this information is found in the D_BOREHOLE table as well as being used for creating the D_INTERVAL_MONITOR table. The maximum depths themselves can come from any of formation depth, reported MOE depth or construction depths. These fields in YC_20130923_BHID are populated and then the final, maximum depth is determined.

We’ll first determine the maximum depth from construction details. We need to make sure that the depths are in ‘m’ or ‘ft’ only.

select

ycb.LOC_ID

,ycb.BH_ID

,ycm.*

from

[MOE_20170905].dbo.YC_20170905_BH_ID as ycb

inner join [MOE_20170905].dbo.M_D_BOREHOLE_CONSTRUCTION as ycm

on ycb.BORE_HOLE_ID=ycm.BH_ID

where

not(ycm.CON_UNIT_OUOM in ('m','ft'))

The common cases are those depths specified using ‘inch’ or ‘cm’ - convert these to the appropriate units (only inches found for MOE_20170905; script not shown).

Script: G_10_14_01_CONS_UNITS.sql

We can now calculate the maximum depth based upon the construction details.

update MOE_20170905.dbo.YC_20170905_BH_ID

set

CON_MAX_DEPTH=yccon.CON_MAX_DEPTH

,CON_MAX_DEPTH_UNITS=yccon.CON_MAX_DEPTH_UNITS

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join

(

select

ycm.BH_ID

,max(ycm.CON_BOT_OUOM) as [CON_MAX_DEPTH]

,ycm.CON_UNIT_OUOM as CON_MAX_DEPTH_UNITS

,COUNT(*) as rcount

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join MOE_20170905.dbo.M_D_BOREHOLE_CONSTRUCTION as ycm

on ycb.BORE_HOLE_ID=ycm.BH_ID

group by

ycm.BH_ID,ycm.CON_UNIT_OUOM

) as yccon

on

ycb.BORE_HOLE_ID=yccon.BH_ID

Script: G_10_14_02_CONS_DEPTH.sql

We’ll now look at the maximum depth as reported by the MOE. Similar to ‘G_10_14_01_CONS_UNITS.sql’, above, check that the units are ‘m’ or ‘ft’ and correct those that are not (only the check is included here, refer to the script for correction details; no corrections were necessary in MOE_20170905).

select

ycb.LOC_ID

,ycb.BH_ID

,moeh.*

from

MOE_20170905.dbo.TblHole as moeh

inner join MOE_20170905.dbo.YC_20170905_BH_ID as ycb

on moeh.Bore_Hole_ID=ycb.BORE_HOLE_ID

where

moeh.Depth_to is not null

and not(moeh.HOLE_DEPTH_UOM in ('m','ft'))

Script: G_10_14_03_MOE_UNITS.sql

Determine the maximum depth as reported by the MOE (and update YC_20170905_BH_ID). Make sure to check the record counts in the case that multiple units are used in specifying the depths (refer to the script-file itself as this latter check is not shown here).

update MOE_20170905.dbo.YC_20170905_BH_ID

set

MOE_MAX_DEPTH=moe_depth.MOE_MAX_DEPTH

,MOE_MAX_DEPTH_UNITS=moe_depth.MOE_MAX_DEPTH_UNITS

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycbh

inner join

(

select

moeh.Bore_Hole_ID

,max(moeh.Depth_to) as MOE_MAX_DEPTH

,moeh.HOLE_DEPTH_UOM as MOE_MAX_DEPTH_UNITS

from

MOE_20170905.dbo.TblHole as moeh

inner join MOE_20170905.dbo.YC_20170905_BH_ID as ycb

on moeh.Bore_Hole_ID=ycb.BORE_HOLE_ID

where

moeh.Depth_to is not null

group by

moeh.Bore_Hole_ID,moeh.HOLE_DEPTH_UOM

) as moe_depth

on ycbh.BORE_HOLE_ID=moe_depth.Bore_Hole_ID

Script: G_10_14_04_MOE_DEPTH.sql

Determine the maximum depth of the borehole based upon the geology information (and update YC_20170905_BH_ID). Make sure to check the record counts in the case that multiple units are used in specifying the depths (refer to the script-file itself as this latter check is not shown here).

update MOE_20170905.dbo.YC_20170905_BH_ID

set

fm_max_depth=fm_depth.FM_MAX_DEPTH

,fm_max_depth_units=fm_depth.FM_MAX_DEPTH_UNITS

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join

(

select

BORE_HOLE_ID

,max(FORMATION_END_DEPTH) as [FM_MAX_DEPTH]

,FORMATION_END_DEPTH_UOM as [FM_MAX_DEPTH_UNITS]

from

MOE_20170905.[dbo].[TblFormation]

where

BORE_HOLE_ID

in

(

select

BORE_HOLE_ID

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

)

and FORMATION_END_DEPTH is not null

group by

BORE_HOLE_ID,FORMATION_END_DEPTH_UOM

) as fm_depth

on ycb.BORE_HOLE_ID=fm_depth.BORE_HOLE_ID

Script: G_10_14_05_FM_DEPTH.sql

Now that the possible depths have been determined, convert all of them to metres (i.e. ‘m’). This value is used to populate MAX_DEPTH_M in YC_20170905_BH_ID. Note that the check and update scripts are not shown (but can be found in the script-file itself).

Script: G_10_14_06_DEPTH_M.sql

Determine the MAX_DEPTH_M from the other depths.

update MOE_20170905.dbo.YC_20170905_BH_ID

set

MAX_DEPTH_M=md.MAX_DEPTH_M

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join

(

select

depths.BORE_HOLE_ID

,max(depths.adepth) as [MAX_DEPTH_M]

from

(

(

select

ycb.BORE_HOLE_ID

,ycb.FM_MAX_DEPTH as adepth

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

where ycb.FM_MAX_DEPTH is not null

)

union

(

select

ycb.BORE_HOLE_ID

,ycb.MOE_MAX_DEPTH as adepth

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

where ycb.MOE_MAX_DEPTH is not null

)

union

(

select

ycb.BORE_HOLE_ID

,ycb.CON_MAX_DEPTH as adepth

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

where ycb.CON_MAX_DEPTH is not null

)

) as depths

group by

depths.BORE_HOLE_ID

) as md

on ycb.BORE_HOLE_ID=md.BORE_HOLE_ID

(For MOE_20170905, 13150 rows were updated.) For those locations with NULL depths (4035), examine alternate options for determining an approximate depth. This includes examination of FM_D_GEOLOGY_FEATURE, ‘TblScreen’, ‘TblPump_Test’ and ‘TblWater’ (not shown; examine script for details). In this case, very few additional depths were determined (refer to script for details) leaving 4024 without depth data.

Script: G_10_14_07_MAX_DEPTH.sql

We can now populate the depths and elevations in D_BOREHOLE.

update MOE_20210119.dbo.M_D_BOREHOLE

set

BH_GND_ELEV=delev.LOC_ELEV

,BH_GND_ELEV_OUOM=delev.LOC_ELEV

,BH_DEM_GND_ELEV=delev.LOC_ELEV

,BH_BOTTOM_ELEV=(delev.LOC_ELEV-ycb.MAX_DEPTH_M)

,BH_BOTTOM_DEPTH=ycb.MAX_DEPTH_M

,BH_BOTTOM_OUOM=ycb.MAX_DEPTH_M

from

MOE_20210119.dbo.M_D_BOREHOLE as dbore

inner join MOE_20210119.dbo.YC_20210119_BH_ID as ycb

on dbore.LOC_ID=ycb.BORE_HOLE_ID

inner join

(

select

dlsh.LOC_ID

,LOC_ELEV

from

MOE_20210119.dbo.M_D_LOCATION_SPATIAL_HIST as dlsh

where

dlsh.LOC_ELEV_CODE=3

-- Only load the SRTM elev if no MNR elev

union

select

dlsh.LOC_ID

,LOC_ELEV

from

MOE_20210119.dbo.M_D_LOCATION_SPATIAL_HIST as dlsh

where

dlsh.LOC_ELEV_CODE=5

) as delev

on dbore.LOC_ID=delev.LOC_ID

Script: G_10_14_08_D_BORE_Update

Note that we’re assuming in the script that only a DEM value will be used to populate the assigned elevation (as found in BH_GND_ELEV). This will need to be adjusted for any MOE location with a QA_COORD_CONFIDENCE_CODE of ‘1’ (i.e. a surveyed location).

G.10.15 Screen information

Before creation of the (compatible) D_INTERVAL_MONITOR table, we need to determine the interval types present (i.e. as represented in R_INT_TYPE_CODE). A look-up table translating the WWDB screen slot size (a text field) to the YCDB screen slot size (a numeric field) must be created first.

select

moes.Slot as MOE_SLOT

,convert(varchar(50),moes.Slot) as YC_SLOT

,cast(null as float) as CONV_YC_SLOT

into MOE_20170905.dbo.YC_20170905_MOE_SLOT

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join MOE_20170905.dbo.TblPipe as moep

on ycb.BORE_HOLE_ID=moep.Bore_Hole_ID

inner join MOE_20170905.dbo.TblScreen as moes

on moep.PIPE_ID=moes.PIPE_ID

where

moes.SCRN_TOP_DEPTH is not null

and moes.SCRN_END_DEPTH is not null

group by

moes.Slot

Note that this look-up table will likely need to be modified. The WWDB MOE_SLOT information is in a ‘text’ form while the YCDB slot format is ‘float’ - the YC_20170905_MOE_SLOT table should have its YC_SLOT field modified until all values can be converted quickly. A test script is available to check user edits (a non-failure indicates the conversion between databases is correct).

select

ycm.MOE_SLOT

,ycm.YC_SLOT

,cast(YC_SLOT as float) as CONV_YC_SLOT

from

MOE_20170905.dbo.YC_20170905_MOE_SLOT as ycm

Script: G_10_15_01_SLOT_SIZE.sql

We can now extract the reported screens from the WWDB (i.e. using ‘TblScreen’, where both the bottom and top depths are present). Substituting the ‘inner join’ with the ‘left outer join’ as indicated will allow a check of the 1-to-1 relationship between the BORE_HOLE_ID and the IDs present in ‘TblPipe’ and ‘TblScreen’ (if the counts are not the same between runs, there are multiple screens in some of the boreholes). Detail is available in the script file. We’re storing the information in a temporary table until all interval types have been added.

select

ycb.BORE_HOLE_ID as TMP_LOC_ID

,18 as tmp_INT_TYPE_CODE

,moeslot.CONV_YC_SLOT as MON_SCREEN_SLOT

,moes.SCRN_MATERIAL as MON_SCREEN_MATERIAL

,moes.SCRN_DIAMETER as MON_DIAMETER_OUOM

,moes.SCRN_DIAMETER_UOM as MON_DIAMETER_UNIT_OUOM

,moes.SCRN_TOP_DEPTH as MON_TOP_OUOM

,moes.SCRN_END_DEPTH as MON_BOT_OUOM

,moes.SCRN_DEPTH_UOM as MON_UNIT_OUOM

,cast(null as varchar(255)) as MON_COMMENT

into MOE_20170905.dbo.YC_20170905_DINTMON

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join

--left outer join

MOE_20170905.dbo.TblPipe as moep

on ycb.BORE_HOLE_ID=moep.Bore_Hole_ID

inner join

--left outer join

MOE_20170905.dbo.TblScreen as moes

on moep.PIPE_ID=moes.PIPE_ID

left outer join

MOE_20170905.dbo.YC_20170905_MOE_SLOT as moeslot

on moes.Slot=moeslot.MOE_SLOT

where

moes.SCRN_TOP_DEPTH is not null

or moes.SCRN_END_DEPTH is not null

Script: G_10_15_02_SCR_REPORT.sql

In this case, we’re using a temporary identifier (TMP_LOC_ID) until an actual INT_ID is to be created (in the case we’ll need multiple INT_IDs for each LOC_ID). Note that we’re ‘parking’ the interval type (i.e. TMP_INT_TYPE_CODE) here temporarily until the D_INTERVAL table is created.

We’ll now find those wells classified as ‘open hole’ - the screen here is considered to be from the bottom of any casing down to the bottom of the hole. (These intervals should not already be in the YC_20170905_DINTMON as there is no reported screen; remember, we’ve loaded the reported screens into this temporary table.)

select

ycb.BORE_HOLE_ID

,ycdim.TMP_LOC_ID

,moebh.*

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join MOE_20170905.dbo.TblBore_Hole as moebh

on ycb.BORE_HOLE_ID=moebh.BORE_HOLE_ID

inner join MOE_20170905.dbo.YC_20170905_DINTMON as ycdim

on ycb.BORE_HOLE_ID=ycdim.TMP_LOC_ID

where

moebh.OPEN_HOLE='Y'

This is provided as a check and should return no screens/intervals (if the previous procedures worked).

We can now determine how many ‘open hole’ wells have casing. This is a check only.

select

ycb.BORE_HOLE_ID

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

inner join MOE_20170905.dbo.TblBore_Hole as moebh

on ycb.BORE_HOLE_ID=moebh.BORE_HOLE_ID

left outer join MOE_20170905.dbo.M_D_BOREHOLE_CONSTRUCTION as ycbc

on ycb.BORE_HOLE_ID=ycbc.BH_ID

where

moebh.OPEN_HOLE='Y'

-- this a list of casing info

and ycbc.CON_SUBTYPE_CODE in (9,16,21,23,25,32)

If any rows are returned, we can then add these as well screen intervals where the interval type is classified as ‘open hole, bottom-of-casing to bottom-of-hole’. If the casing depths return a NULL value, the maximum construction depth from YC_20180530_BH_ID is substituted. In all cases when populating the temporary interval monitor table (i.e. YC_20170905_DINTMON), we’re not checking against NULL tops or zero-length screens. This is to be considered at a later step. For MOE_20170905, no rows were added from this process.

insert into [MOE_20180530].dbo.YC_20180530_DINTMON

(TMP_LOC_ID,TMP_INT_TYPE_CODE,MON_TOP_OUOM,MON_BOT_OUOM,MON_UNIT_OUOM,MON_COMMENT)

select

ycb.BORE_HOLE_ID as TMP_LOC_ID

,21 as TMP_INT_TYPE_CODE

--,cd.CASING_DEPTH as MON_TOP_OUOM

,case

when cd.CASING_DEPTH is not null then cd.CASING_DEPTH

else ycb.CON_MAX_DEPTH

end as MON_TOP_OUOM

,ycb.MAX_DEPTH_M as MON_BOT_OUOM

,'m' as MON_UNIT_OUOM

--,(ycb.MAX_DEPTH_M-cd.CASING_DEPTH) as DIFF_OPEN_HOLE

,'open hole; bottom-of-casing to bottom-of-hole' as MON_COMMENT

from

[MOE_20180530].dbo.YC_20180530_BH_ID as ycb

inner join [MOE_20180530].dbo.TblBore_Hole as moebh

on ycb.BORE_HOLE_ID=moebh.BORE_HOLE_ID

left outer join

(

select

cd.BH_ID

,max(CON_BOT_OUOM) as [CASING_DEPTH]

from

(

select

ycbc.BH_ID

,case

when ycbc.CON_UNIT_OUOM='ft' then ycbc.CON_BOT_OUOM*0.3048

else ycbc.CON_BOT_OUOM

end

as CON_BOT_OUOM

from

[MOE_20180530].dbo.M_D_BOREHOLE_CONSTRUCTION as ycbc

where

ycbc.CON_SUBTYPE_CODE in (9,16,21,23,25,32)

) as cd

group by

cd.BH_ID

) as cd

on

ycb.BH_ID=cd.BH_ID

where

moebh.OPEN_HOLE='Y'

--and (ycb.MAX_DEPTH_M-cd.CASING_DEPTH)>0

Script: G_10_15_03_SCR_OPENHOLE.sql

We would now examine the number of screen intervals that are reported as ‘open hole’ but do not have any casing information associated with them. In addition, we’re only interested in locations that fall within the YPDT-CAMC area. The SQL statements and explanation are thus only found in the external script. No rows were returned from the MOE_20170905 database. From the MOE_20180530 database, 18 records were returned - these were handled, above (Section G.10.15.03), by applying the maximum construction depth.

Script: G_10_15_04_SCR_OPENHOLE_NC.sql

We need to determine, now, how many locations still require a screen interval to be assigned and the particular ‘assumed’ type to apply.

Currently, how many locations have screens assigned?

select

COUNT(*) as [Distinct_LOC_ID]

from

(

select

ycdim.TMP_LOC_ID

,COUNT(*) as rcount

from

MOE_20170905.dbo.YC_20170905_DINTMON ycdim

group by

ycdim.TMP_LOC_ID

) as test

How many locations/intervals (using a one-to-one relationship for these MOE boreholes) remain to be assigned.

select

COUNT(*) as [To_Assign_tmp_LOC_IDs]

from

MOE_20170905.dbo.YC_20170905_BH_ID as ybc

where

ybc.BORE_HOLE_ID

not in

(

select distinct(tmp_LOC_ID) from MOE_20170905.dbo.YC_20170905_DINTMON

)

Script: G_10_15_05_SCR_NUMBER.sql

Various assumptions are made for applying the screen/interval types to the remainder of the boreholes.

We’ll now check for the existence of bedrock within the hole. We can then assign the interval type ‘Assumed Open Hole (Top of Bedrock to Bottom of Hole)’. Bedrock types are defined in R_GEOL_MAT1_CODE as having a ROCK value of ‘1’ (i.e. a ‘True’ value). Add these to the YC_20170905_DINTMON table.

insert into MOE_20170905.dbo.YC_20170905_DINTMON

(tmp_LOC_ID,tmp_INT_TYPE_CODE,MON_TOP_OUOM,MON_BOT_OUOM,MON_UNIT_OUOM,MON_COMMENT)

select

bi.LOC_ID as tmp_LOC_ID

,22 as tmp_INT_TYPE_CODE

,bi.MON_TOP_OUOM

,case

when ybc.MAX_DEPTH_M>bi.MON_BOT_OUOM then ybc.MAX_DEPTH_M

else bi.MON_BOT_OUOM

end

as MON_BOT_OUOM

,'m' as MON_UNIT_OUOM

,'bedrock, no valid casing; open hole, top-of-bedrock to bottom-of-hole' as MON_COMMENT

from

(

select

fmdgl.LOC_ID

,case

when fmdgl.GEOL_UNIT_OUOM='ft' then MIN(fmdgl.GEOL_TOP_OUOM)*0.3048

else MIN(fmdgl.GEOL_TOP_OUOM)

end as MON_TOP_OUOM

,case

when fmdgl.GEOL_UNIT_OUOM='ft' then MAX(fmdgl.GEOL_BOT_OUOM)*0.3048

else MAX(fmdgl.GEOL_BOT_OUOM)

end as MON_BOT_OUOM

from

MOE_20170905.dbo.M_D_GEOLOGY_LAYER as fmdgl

inner join OAK_20160831_MASTER.dbo.R_GEOL_MAT1_CODE as rgmc

on fmdgl.GEOL_MAT1_CODE=rgmc.GEOL_MAT1_CODE

where

fmdgl.LOC_ID

in

(

select

ybc.BORE_HOLE_ID as LOC_ID

from

MOE_20170905.dbo.YC_20170905_BH_ID as ybc

where

ybc.BORE_HOLE_ID

not in

( select tmp_LOC_ID from MOE_20170905.dbo.YC_20170905_DINTMON )

)

and rgmc.GEOL_MAT1_ROCK=1

group by

fmdgl.LOC_ID,fmdgl.GEOL_UNIT_OUOM

) as bi

inner join MOE_20170905.dbo.YC_20170905_BH_ID as ybc

on bi.LOC_ID=ybc.BORE_HOLE_ID

Script: G_10_15_06_SCR_BEDROCK.sql

We could use the scripts from G_10_15_05_SCR_NUMBER to determine how many locations now require intervals to be assigned (as a check). For this remainder we will use the interval type ‘Overburden - Assumed (1ft above bottom of hole)’ (i.e. a value of ‘19’ as found in R_INT_TYPE_CODE; when we’re assigning a screen interval in meters, though, a ‘0.3’ metre value is used instead). Note that for these screens/intervals, we’re imposing the metre as the depth unit (instead of checking to see how the various depth units are applied for any particular location). Now, if the number of rows returned here doesn’t match the number of rows expected, check the records that do not have a valid maximum depth (to make up the difference).

The number of rows returned here should make up the remainder (otherwise some troubleshooting will be required). Add the overburden screens/intervals.

insert into MOE_20170905.dbo.YC_20170905_DINTMON

(tmp_LOC_ID,tmp_INT_TYPE_CODE,MON_TOP_OUOM,MON_BOT_OUOM,MON_UNIT_OUOM,MON_COMMENT)

select

ycb.BORE_HOLE_ID as tmp_LOC_ID

,19 as tmp_INT_TYPE_CODE

,(ycb.MAX_DEPTH_M-0.3) as MON_TOP_OUOM

,ycb.MAX_DEPTH_M as MON_BOT_OUOM

,'m' as MON_UNIT_OUOM

,'overburden; assumed screen 0.3m above bottom' as MON_COMMENT

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

where

ycb.BORE_HOLE_ID not in

( select tmp_LOC_ID from MOE_20170905.dbo.YC_20170905_DINTMON )

and ycb.MAX_DEPTH_M is not null

Script: G_10_15_07_SCR_OVERBUR.sql

The remaining non-assigned locations (i.e. without an assigned interval) are considered to have no valid information for creation of a screen. These will be given an interval type of ‘Screen Information Omitted’ (a value of ‘28’).

Note that these are to be added to YC_20170905_DINTMON temporarily only (as placeholders). They will be used for populating FM_D_INTERVAL but will not be transferred to FM_D_INTERVAL_MONITOR.

insert into MOE_20170905.dbo.YC_20170905_DINTMON

(TMP_LOC_ID,TMP_INT_TYPE_CODE,MON_COMMENT)

select

ycb.BORE_HOLE_ID as tmp_LOC_ID

,28 as tmp_INT_TYPE_CODE

,'no valid screen determined' as MON_COMMENT

from

MOE_20170905.dbo.YC_20170905_BH_ID as ycb

where

ycb.BORE_HOLE_ID

not in

( select tmp_LOC_ID from MOE_20170905.dbo.YC_20170905_DINTMON )

and ycb.MAX_DEPTH_M is null

Script: G_10_15_08_SCR_NODATA.sql

Make sure that the MON_TOP_OUOM is above (smaller than) MON_BOT_OUOM.

update MOE_20170905.dbo.YC_20170905_DINTMON

set

MON_TOP_OUOM=MON_BOT_OUOM

,MON_BOT_OUOM=MON_TOP_OUOM

where

MON_BOT_OUOM<MON_TOP_OUOM

We can now copy the information from YC_20170905_DINTMON to M_D_INTERVAL_MONITOR. We should first check the number of records in the first table against the number of valid locations from YC_20170905_BH_ID (not shown, see the script file, below, for details). In MOE_20160531, a value of 28,575 versus 28,188 was determined; there must be some locations with multiple intervals (in MOE_20170905, no duplicates were found). Check that there are no duplicates and then check that there is only a single static water level reading per BORE_HOLE_ID/PIPE_ID (from the original MOE WWDB information). Only the final SQL statement is shown (refer to the script file for additional details).

select

t3.BORE_HOLE_ID

,t3.rcount

from

(

select

t2.BORE_HOLE_ID

,COUNT(*) as rcount

from

(

--*****

SELECT

moept.[PIPE_ID]

,t1.BORE_HOLE_ID

,[WELL_ID]

,[Static_lev]

,[LEVELS_UOM]

FROM

MOE_20170905.[dbo].[TblPump_Test] as moept

inner join

(

select

moetp.PIPE_ID

,ycb.BORE_HOLE_ID

from

MOE_20170905.dbo.[YC_20170905_BH_ID] as ycb

inner join MOE_20170905.dbo.TblPipe as moetp

on ycb.BORE_HOLE_ID=moetp.Bore_Hole_ID

) as t1

on moept.PIPE_ID=t1.PIPE_ID

where

moept.Static_lev is not null

--*****

) as t2

group by

t2.BORE_HOLE_ID

) as t3

where

t3.rcount>1

No locations were duplicated. Check for duplicate (or null) values for screen info.

select

test.TMP_LOC_ID

,ycd.*

from

(

select

TMP_LOC_ID

,COUNT(*) as rcount

from

MOE_20170905.dbo.YC_20170905_DINTMON as ycd

group by

TMP_LOC_ID,MON_SCREEN_SLOT,MON_SCREEN_MATERIAL,MON_DIAMETER_OUOM,

MON_DIAMETER_UNIT_OUOM,MON_TOP_OUOM,MON_BOT_OUOM

) as test

inner join

MOE_20170905.dbo.YC_20170905_DINTMON as ycd

on test.TMP_LOC_ID=ycd.TMP_LOC_ID

where

test.rcount>1

order by

test.TMP_LOC_ID

There are 0 here for MOE_20170905 (in MOE_20160531 there were 20); any found , here, would need to be corrected after assigning a SYS_RECORD_ID.

We’ll copy the YC_20170905_DINTMON to M_D_INTERVAL_MONITOR adding a blank INT_ID column and a counter SYS_RECORD_ID column.

Check that the number of rows from the source table matches the row number count in the output (not shown), then create the M_D_INTERVAL_MONITOR table.

select

TMP_LOC_ID as INT_ID

,dim.tmp_INT_TYPE_CODE

,dim.MON_SCREEN_SLOT

,cast(moeccm.DES as varchar(255)) as MON_SCREEN_MATERIAL

,dim.MON_DIAMETER_OUOM

,dim.MON_DIAMETER_UNIT_OUOM

,dim.MON_TOP_OUOM

,dim.MON_BOT_OUOM

,dim.MON_UNIT_OUOM

,dim.MON_COMMENT

,cast(null as int) as MON_FLOWING

,row_number() over (order by dim.TMP_LOC_ID) as SYS_RECORD_ID

into MOE_20170905.dbo.M_D_INTERVAL_MONITOR

from

MOE_20170905.dbo.YC_20170905_DINTMON as dim

left outer join MOE_20170905.dbo._code_casing_material as moeccm

on dim.MON_SCREEN_MATERIAL=moeccm.CODE

Note that we’re copying TMP_LOC_ID to INT_ID (temporarily) and using a row counter for SYS_RECORD_ID. Delete any duplicates (that we noticed earlier; this occurred in MOE_20160531).

delete from MOE_20160531.dbo.M_D_INTERVAL_MONITOR

where

SYS_RECORD_ID in

(

select

dim.SYS_RECORD_ID

from

MOE_20160531.dbo.M_D_INTERVAL_MONITOR as dim

inner join

(

select

t.INT_ID

,t.keep_SRI

from

(

select

INT_ID

,COUNT(*) as rcount

,min(SYS_RECORD_ID) as keep_SRI

from

[MOE_20160531].dbo.M_D_INTERVAL_MONITOR as dim

group by

INT_ID,MON_SCREEN_SLOT,MON_SCREEN_MATERIAL,MON_DIAMETER_OUOM,MON_DIAMETER_UNIT_OUOM,MON_TOP_OUOM,MON_BOT_OUOM

) as t

where t.rcount>1

) as t2

on dim.INT_ID=t2.INT_ID

where

dim.SYS_RECORD_ID<>t2.keep_SRI

Make sure that we’re catching all the locations/intervals.

select

b.*

from

MOE_20170905.dbo.YC_20170905_BH_ID as b

where

BORE_HOLE_ID

not in

(

select

INT_ID

from

MOE_20170905.dbo.M_D_INTERVAL_MONITOR

group by

INT_ID

)

If any are missing, re-introduce them from YC_20170905_DINTMON (not shown).

Script: G_10_15_09_SCR_INT_ID_SRI.sql

G.10.16 Screen information - D_INTERVAL

We can now create the actual intervals for M_D_INTERVAL using the information in M_D_LOCATION and M_D_INTERVAL_MONITOR. Note that the LOC_ORIGINAL_NAME (i.e. WELL_ID) is being assigned to INT_NAME and the BORE_HOLE_ID (from YC_20160531_BH_ID) to INT_NAME_ALT2.

select

dim.INT_ID

,ycb.BORE_HOLE_ID as LOC_ID

,dloc.LOC_ORIGINAL_NAME as INT_NAME

,ycb.BORE_HOLE_ID as INT_NAME_ALT2

,dim.tmp_INT_TYPE_CODE as INT_TYPE_CODE

,case

when dloc.LOC_START_DATE is not null then dloc.LOC_START_DATE

else cast('1867-07-01' as datetime)

end as INT_START_DATE

,cast(1 as int) as INT_CONFIDENTIALITY_CODE

,cast(1 as int) as INT_ACTIVE

,cast(519 as int) as [DATA_ID]

into MOE_20170905.dbo.M_D_INTERVAL

from

(

select

dim.INT_ID

,dim.INT_ID as LOC_ID

,dim.tmp_INT_TYPE_CODE

from

MOE_20170905.dbo.M_D_INTERVAL_MONITOR as dim

group by

dim.INT_ID,dim.tmp_INT_TYPE_CODE

) as dim

inner join MOE_20170905.dbo.YC_20170905_BH_ID as ycb

on dim.LOC_ID=ycb.BORE_HOLE_ID

inner join MOE_20170905.dbo.M_D_LOCATION as dloc

on ycb.BORE_HOLE_ID=dloc.LOC_ID

Script: G_10_16_01_M_D_INTERVAL.sql

Make sure that there isn’t an error here regarding interval identifiers - there should be no duplicates (check not shown).

G.10.17 Interval reference elevation

We can now build the M_D_INTERVAL_REF_ELEV table using the M_D_INTERVAL and M_D_BOREHOLE tables (we’ll use a row count for populating the SYS_RECORD_ID). Note that we’re assuming a ‘0.75’ metre stickup (assigned to REF_STICK_UP; previously this was assigned to REF_POINT) for all MOE WWDB wells.

SELECT

dint.[INT_ID]

,case

when dint.INT_START_DATE is not null then dint.INT_START_DATE

else cast('1867-07-01' as datetime)

end

as REF_ELEV_START_DATE

,cast('0.75' as varchar(50)) as REF_STICK_UP

,(delev.bh_gnd_elev+0.75) as [REF_ELEV]

,(delev.bh_gnd_elev+0.75) as [REF_ELEV_OUOM]

,cast('masl' as varchar(50)) as REF_ELEV_UNIT_OUOM

,cast('ASSIGNED_ELEV + 0.75m' as varchar(255)) as REF_COMMENT

,row_number() over (order by dint.INT_ID) as SYS_RECORD_ID

,convert(int,523) as [DATA_ID]

into MOE_20220328.dbo.M_D_INTERVAL_REF_ELEV

FROM

MOE_20220328.[dbo].[M_D_INTERVAL] as dint